Bag

Artful Sewing Precise Crafting

Advanced Equipment

Years of Industry Production Experience

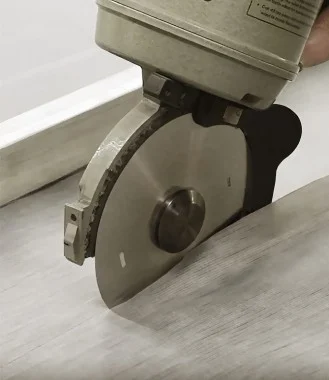

Our factory is equipped with four advanced cutting machines, operated by a technical team with over a decade of expertise in cutting luggage materials. This ensures meticulous quality, whether you're producing custom bags in small batches or scaling up for high-volume orders.

With solid strength

Our Paramount Focus

The equipment is advanced and sufficient. We possess 200 advanced machines, such as fully automatic folding machines, computerized embroidery machines, and computerized synchronous sewing machines. There are more than 200 skilled workers in the factory, guaranteeing high-quality and high-volume production services.

Service Advantages

The Path to Brand Elevation

Our business, order-following, customer service, and after-sales service teams, consisting of 10 - 20 people, offer one-on-one services throughout the whole process from material selection, sample making to finished product production, paying attention to every detail.

Development Advantages

Swift Delivery & Reliable After-Sales

We have a professional and experienced design team. Having been working hard in the field of luggage development for more than ten years, they firmly grasp industry trends and regularly introduce creative and fashionable new products.

Our Factory And Facilities

At MoDu Fashion, we support brands and designers with end-to-end bag production solutions—combining technical manufacturing capability with hands-on creative support.

From structured travel cases and premium backpacks to soft accessories like totes, cross-bodies, and vanity bags, we support brands and designers with flexible options—including custom bag tags and canvas bags bulk solutions. Our curated factory network ensures every item, from the smallest custom bag to large production runs, is crafted with both aesthetics and function in mind.

On-Ground Support with Production Excellence

The involvement of high tech cutting laser machines and computerized sewing machines results in precise cutting and sewing, which can greatly increase efficiency by 30%.

Advanced Equipment

Our production facilities in Zhejiang & Guangzhou, China are equipped with advanced machinery—laser cutters, computer-controlled sewing units, and precision mold systems—enabling streamlined, accurate execution at scale. Paired with our Shanghai office, our localized team provides offline support, factory coordination, and hands-on sampling management to help international clients gain full transparency and peace of mind throughout the process. We’re not just making bags—we’re building a reliable bridge between your concept and a finished product you’re proud to sell.

Our Factory And Facilities

At MoDu Fashion, we support brands and designers with end-to-end bag production solutions—combining technical manufacturing capability with hands-on creative support. From structured travel cases and premium backpacks to soft accessories like totes, cross-bodies, and vanity bags, our curated factory network ensures every item is crafted to meet the demands of both aesthetics and function. We work across a wide range of materials including leather, PU, canvas, nylon, rattan, and recycled textiles, providing flexible options for both seasonal launches and long-term collections.

On-Ground Support with Production Excellence

The involvement of high tech cutting laser machines and computerized sewing machines results in precise cutting and sewing, which can greatly increase efficiency by 30%.

Advanced Equipment

Our production facilities in Zhejiang & Guangzhou, China are equipped with advanced machinery—laser cutters, computer-controlled sewing units, and precision mold systems—enabling streamlined, accurate execution at scale. Paired with our Shanghai office, our localized team provides offline support, factory coordination, and hands-on sampling management to help international clients gain full transparency and peace of mind throughout the process. We’re not just making bags—we’re building a reliable bridge between your concept and a finished product you’re proud to sell.

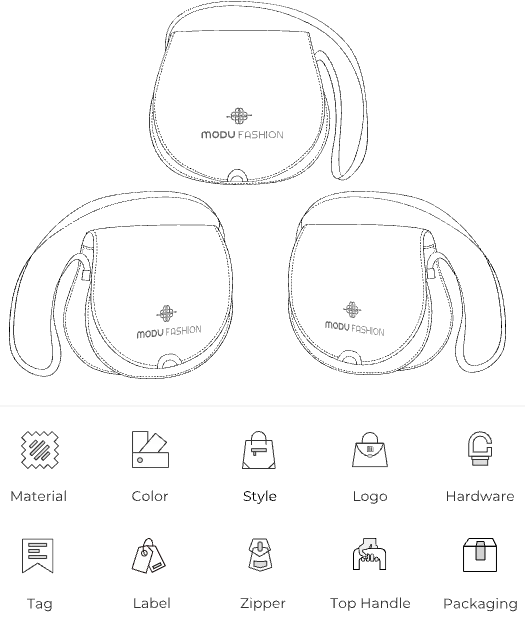

Customization Options

Crafting dreams stitch by stitch – for creators and corporations alike. Whether you’re an individual envisioning a unique statement piece or a wholesaler requiring bulk custom orders, our end-to-end solutions transform ideas into premium products.

Benefit from:

- 1-on-1 Design Consultations

- Prototype Sampling (1pc available)

- Scalable Production (1-10,000+ units)

- Dedicated Quality Control

Experience seamless customization from sketch to delivery. Your vision, our craftsmanship – perfectly aligned.

Bag styles we can make

Bring your vision to life with our premium bag customization! We expertly craft all market-popular styles. Have a unique design? We materialize your sketches. Prefer ready inspiration? Explore our curated catalog featuring customizable designs.Stand out with bespoke bags tailored to your exact needs.

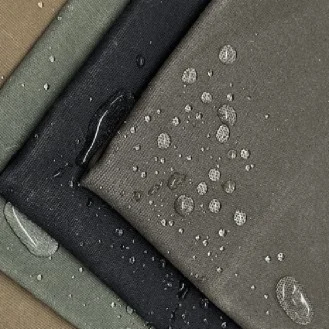

Bag Materia Resources

Discover our premium material range for bag customization! All sourced for durability, texture, and style flexibility. Select your ideal fabric to match design vision and functional needs. Quality assured.

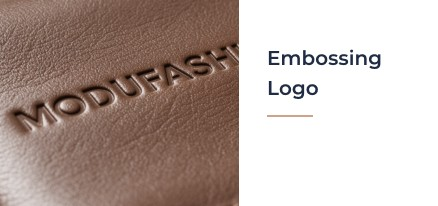

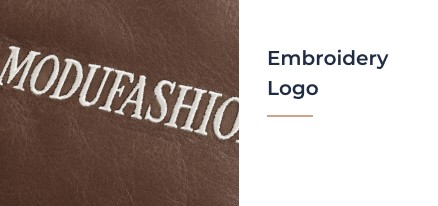

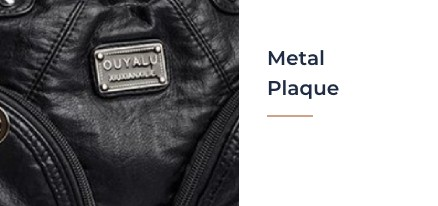

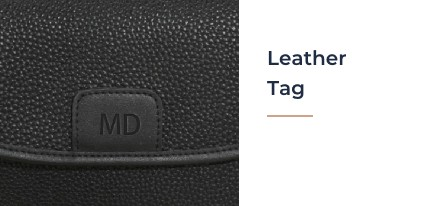

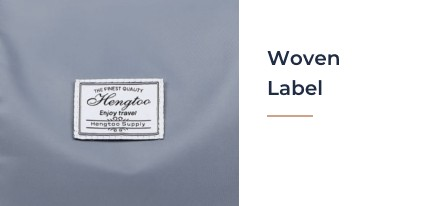

Bag Logo Resources

Discover our premium material range for bag customization! All sourced for durability, texture, and style flexibility. Select your ideal fabric to match design vision and functional needs. Quality assured.

Bag Decorate Resources

Transform bags with premium decorative elements! Elevate style and functionality through customizable accents. Mix and match hardware to create unique brand statements on any bag style

Product production process

01

Preparation Phase

Perform various basic preparations for production. Prepare relevant technical documents (such as process sheets, materials, and pattern drawings).

02

Material Handling

According to the production plan, collect the required main and auxiliary materials, conduct necessary inspections and complete preliminary pre-processing work.

03

Material Cutting

Components to required shapes and dimensions. Using design patterns and professional cutting equipment/tools, accurately cut prepared materials into the individual parts needed for the product.

04

Stitching/Assembly

Join prepared parts per construction specs to form primary structures or sub-assemblies (e.g. handles, frames, reinforcement panels).

05

Stitching finished products

Complete the splicing and sewing of the product body or main components to produce the finished product.

06

First Quality Inspection

The finished product undergoes a first comprehensive quality inspection.

Checkpoints include stitching quality and dimensional compliance.

07

Second Quality Inspection

A more rigorous second inspection is conducted on completions that have passed the first inspection. The focus is on verifying that any issues found in the first inspection have been fixed.

08

Finished Product Packaging

Perform standardized packaging of approved finished products. Follow standard packaging procedures for sealing, labeling, and cartoning to ensure product safety.

09

Finished Goods Dispatch

Organize outbound logistics and shipment of finished goods. Tracking shipment status to ensure qualified products are delivered accurately, safely, and on time to the customer’s specified location.

FAQ About Bag Customization and Production

Our MOQ depends on the material used:

Genuine leather bags: Minimum 100 pieces per style

Other materials (canvas, PU, nylon, etc.): Minimum 300 pieces per style

Yes. We offer OEM (custom design) and ODM (based on our catalog) bag manufacturing. You can share your tech pack or inspiration images, and our team will help develop a custom sample.

Yes. Sample development typically takes 10–14 working days after design and material confirmation. We recommend starting with a sample to review size, material, and quality before placing a bulk order.

Absolutely. We source a wide range of sustainable fabrics (recycled nylon, organic cotton canvas, etc.) and premium materials such as genuine leather, vegan leather, and waxed canvas. Let us know your material goals and we’ll propose suitable options.

Our standard lead time is 30–45 days after sample approval and payment, depending on the order size and materials.

We produce a wide range of bags including tote bags, crossbody bags, backpacks, travel duffels, cosmetic pouches, shoulder bags, and tech organizers, among others.

Yes. We offer custom embroidery, print, embossing, metal logo, and custom tags/labels. We also provide bespoke packaging options to match your brand presentation.

Yes. Every order undergoes strict in-house quality control during production and before packing. Third-party QCservices can also be arranged upon request.

For new customers, we require T/T payment in advance. Once the payment is received, we will begin sampling or production immediately. For long-term partnerships, flexible payment terms can be discussed.

Yes. We offer both FOB and DDP shipping options and can help coordinate delivery via air, sea, or express depending on your budget and timeline.

For new clients, we typically work on T/T (telegraphic transfer) payment in advance. Once we confirm your order, we will issue a Proforma Invoice (PI) for your review and payment. As soon as the payment is received, we’ll start the sampling or bulk production right away. For returning clients or larger orders, we may offer more flexible terms.